- Series Charging and Discharging Cell Formation System

- Charge and Discharge-Discharge energy recovery series

- Charge and Discharge Test Equipment-Portable

- Charge and Discharge Test Equipment-Single Independent Module

- Charge and Discharge Test Equipment-Low Current

- Charge and Discharge Test Equipment - Single machine multi-Channel series

- Charge and Discharge Test Equipment-High-speed Recording R Series

- Battery Management System BMS - PCBA Tester

- Battery Semi-test / Final test Testing Equipment

- Calibrator Equipment

- Peripheral Devices R series

- Peripheral Devices Thinklab series

- Software and hardware manual for the portable device

The ACFS-SCD combines advanced Series Charge-Discharge technology, Multiple Stage Constant Current (MSCC) charging, and Dynamic Bypass (DYBP), to achieve hardware and operational cost savings, high discharge recovery efficiency, and unparalleled cell formation consistency.

The ACFS-SCD advanced cell formation system is a formation and grading solution based on a series charge-discharge model.It integrates MSCC, DYBP, and High-Voltage, High-Efficiency Discharge Recovery technologies, designed specifically for large-scale production lines demanding high consistency, high energy recovery efficiency, low setup costs, and minimal maintenance requirements.Its innovative design significantly reduces hardware requirements and supports flexible applications for various cell chemistries, empowering customers to achieve both increased productivity and cost efficiency.

Applicable Fields:

System Advantages:

- Lithium Battery Manufacturing: Pre-charging, first activation charging, second activation charge-discharge, and capacity grading for cell production.

- Electric Vehicle Industry: Formation and consistency testing of single cells before assembling into battery packs.

- Energy Storage Systems: Formation and testing of large-scale energy storage batteries.

- Industrial Battery Manufacturing: Formation of lead-acid and lithium batteries for industrial equipment, and testing of nickel-metal hydride batteries.

- General Cell Applications: Capacity grading and incoming inspection of battery cells

- 92% Reduction in Hardware Requirements, 90% Reduction in Calibration Needs

- 92% Improvement in Capacity Consistency, 80% Reduction in Maintenance Requirements

- High-Voltage Discharge Recovery Efficiency > 88%

- Multiple Stage Constant Current Charging (MSCC)

- Uninterrupted Current with Dynamic Bypass (DYBP)

- Bi-Directional AC/DC Power Module with safety certifications: IEC62477-1, IEC62116, TUV/UL 62368-1, CB/UL/TUV 62368, CE

- Output Accuracy:Charge ±0.02%、Discharge ±0.05%

- Continuous monitoring and alert system for fixture line impedance and ambient temperature

Traditional Cell Formation Issues

Challenges of Traditional One-to-One Formation

The traditional one-to-one formation method, though widely used, has become increasingly limited. It struggles to address the rapid growth of electric vehicles, energy storage systems, and consumer electronics.Equipping each cell with an independent hardware channel enables precise control but creates significant challenges: complex equipment, high costs, and difficult maintenance. Additionally, inefficiencies in energy use, inconsistent performance, and low production efficiency make it unsuitable for modern demands.

High Hardware Costs and Burden

raditional formation demands a dedicated channel per cell, driving up hardware, space, maintenance, and energy costs.

Example: 10,000 cells require 10,000 channels, significantly increasing calibration and repair expenses.

Frequent Calibration and Maintenance

- More channels mean higher calibration and maintenance demands, reducing system availability and prolonging production cycles.

- Calibrating 10,000 channels at 3 minutes each takes 500 hours. This is time-intensive and severely affects production capacity.

- Complex Repairs:Module failures require extensive disassembly, causing long downtimes and difficult maintenance.

Energy Waste and High Operational Costs

- Traditional formation equipment suffers from low energy recovery efficiency. The low voltage of individual cells during discharge leads to significant energy loss as heat, requiring additional cooling systems to manage operating temperatures. This not only wastes energy but also increases long-term operational costs.

Challenges in Ensuring Cell Consistency

- Traditional one-to-one formation relies on the stability of individual channels. Inadequate calibration or maintenance of certain channels results in inconsistent cell performance after formation.

- Large Batch Variations:Capacity discrepancies between cells due to channel precision errors affect downstream module assembly and overall system performance.

Traditional formation Technology faces multiple challenges, including high hardware costs, large space requirements, complex calibration and maintenance, energy waste, and insufficient cell consistency. As the market increasingly demands efficient, low-cost, and large-scale production, these issues have become significant barriers to the growth of the cell industry.The ACFS-SCD system, with its innovative design and outstanding performance, offers efficient and sustainable solutions to these longstanding problems, enabling companies to achieve a comprehensive upgrade in their formation processes.

Innovative Formation, Boosting Efficiency

The ACFS-SCD system, an advanced formation solution based on a series charge-discharge model, is designed to meet modern production line demands for

High performance, Low cost, and Outstanding consistency.

By integrating Multiple Stage Constant Current charging (MSCC), Dynamic Bypass (DYBP) technology, and high-efficiency energy recovery (Efficiency > 88%), the ACFS-SCD not only revolutionizes traditional formation processes but also reduces hardware requirements by 92% through its modular design, making it an ideal solution for the power battery, energy storage system, and industrial battery sectors.

Series Charge-Discharge, SCD

Dynamic Bypass, DYBP

Dynamic Bypass Technology is one of the core innovations of the ACFS-SCD system, ensuring precise voltage and current control and efficient operation during the formation process. When a cell reaches its target voltage (e.g., CV point), the system automatically activates the bypass module to isolate the cell from the main charge-discharge path. The bypass switching is completed within milliseconds (<10ms) with instantaneous current ripple controlled at Max. 300mA for <1ms, ensuring stability and safety throughout the formation process.

Key Features of Dynamic Bypass Technology:

- Real-Time Response:It enables fast bypass switching without interrupting the charging or discharging process of other cells.

- Stable and Efficient:During bypass, other cells continue their charge-discharge cycles, ensuring uninterrupted formation in the series circuit and enhancing production efficiency.

- Consistency Assurance:Prevents overcharging or over-discharging of cells, ensuring uniform performance and capacity across the batch.

- Single Bypass:Used in the final stage of MSCC or during discharge.

- Ensures each cell reaches the specified CV and cut-off current point during charging.Ensures each cell discharges to the specified cut-off voltage point.

- All Bypass:Applied during the MSCC process.

- Automatically tracks the highest-voltage cell in the series and adjusts MSCC current stages accordingly.

- Start Bypass:Allows 1 to 12 cells to charge or discharge even if the number is incomplete.

Multiple Stage Constant Current, MSCC

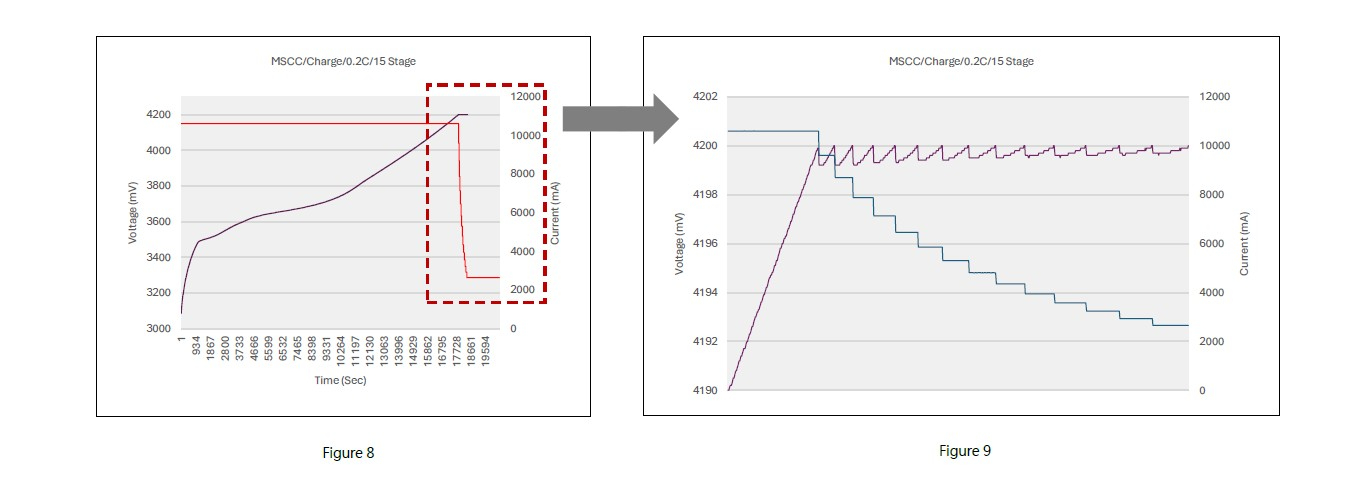

MSCC (Multiple Stage Constant Current) technology is a key feature of the ACFS-SCD system, designed to maximize cell formation consistency and efficiency through precise multi-stage current control. The system divides the entire charging process into multiple current stages (1–100) based on user settings and dynamically adjusts the current for each stage as cell voltages progress. This approach emulates the traditional CV mode, ensuring each cell undergoes formation under optimal conditions.

ThinkFM Software provides automated MSCC calculation functionality. Users only need to input the starting current, ending current, cut-off voltage, and the number of MSCC stages. ThinkFM automatically computes the duration, current, and voltage for each stage based on the user-defined parameters.

Validation:MSCC/Charge/0.2C/15 Stage Series connection of multiple cells – highest voltage tracking.

Validation:MSCC/Charge/0.2C/15 Stage

Current High-Precision Control

Precise Current Control for Superior Consistency

Conventional AC/DC bidirectional power supplies used in the industry achieve current control accuracy of approximately ±0.1%. In contrast, the ACFS-SCD system leverages advanced technology to enhance current control precision to ±0.02%, enabling more efficient and stable cell formation

1. High Consistency in Series Cells:The single-unit series architecture ensures each cell undergoes formation under the same current, significantly improving capacity consistency in mass production.

2. Precise Synchronization Between Systems:High current precision matching between units minimizes errors, ensuring exceptional consistency across different cell production batches.

3. Quality Assurance in Mass Production:Current control accuracy is enhanced to ±0.02%, a fivefold improvement over traditional methods. This minimizes performance deviations during formation. It further enhances reliability and yield rates in large-scale production.

Application Value:

Through the precise control of the ACFS-SCD system and the series consistency design, customers can easily achieve high standards of cell capacity consistency. This provides excellent product quality and competitive advantages for industries such as power batteries, energy storage systems, and consumer electronics. This innovative technology ensures that every cell in mass production meets the ideal specifications, facilitating efficient production line operations and higher product output efficiency.

World-Class Safety Standards and Certification

Class Safety Standards and Certifications

Unlike non-standard custom products, the AC/DC bidirectional power modules meet IEC62116, TUV/UL 62368-1, CB/UL/TUV 62368, and CE certification requirements. The AC parallel functionality design also complies with IEC 62477-1 standards. These certifications ensure stability during high-load operation while significantly reducing potential system risks.

Multi-Layer Protection Mechanisms

Built-in protections against overload, overheating, and short circuits prevent safety hazards caused by equipment failures. Compared to uncertified self-produced products on the market, this power module's safety has been validated in various applications, providing higher reliability for formation systems.

MIT Global Standardized Products with Stable and Reliable Quality

Using mass-production products from internationally renowned manufacturers ensures batch consistency and eliminates the supply instability issues commonly faced by self-produced items, providing a robust supply chain for the system.

High-Voltage, High-Efficiency Discharge Recovery

Cell Series Connection – High Voltage and High Efficiency – Discharge Recovery

In the ACFS-SCD system, high-voltage, high-efficiency discharge recovery is achieved by connecting 12 battery cells in series, and using a bidirectional AC/DC power module to feed the DC energy back into the grid. This not only significantly reduces line losses but also enables a recovery efficiency exceeding 88%.

Discharge Current vs. DC-AC Conversion Efficiency Curve:

Note 1: The DC-AC conversion efficiency testing method refers to "Discharge Regeneration Efficiency Calculation_V1.3_20250425".

Note 2: The efficiency calculation includes line losses from RS3 and RS4.

Clamp fixture line impedance monitoring

Continuous and uninterrupted monitoring of the circuit impedance from the machine's output terminal to the cell tab voltage sampling point during charging and discharging.Scanning and measuring the circuit impedance at fixed time intervals (configurable from 1 to 100 seconds), and triggering an over-resistance (ORP) alarm if the measured impedance exceeds the set threshold.

As shown in the figure on the right

From the device output terminal to the cell voltage sampling points V+/V-, the current lines (I+/I-) pass through various nodes (such as terminal blocks, quick connectors, etc.), ultimately connecting to the tab fixture.During charging and discharging, the device continuously monitors the R1+R2 value to check if it exceeds the over-resistance (ORP) alarm threshold

Battery tray ambient temperature monitoring

Continuous and uninterrupted monitoring of the battery fixture tray's ambient temperature during charging and discharging.

Each fixture tray is equipped with 4/8 temperature points, scanning and measuring the ambient temperature of the battery fixture tray at fixed intervals (1 second). The system checks the temperature against the set threshold and triggers an over-temperature (OTP) alarm if necessary.

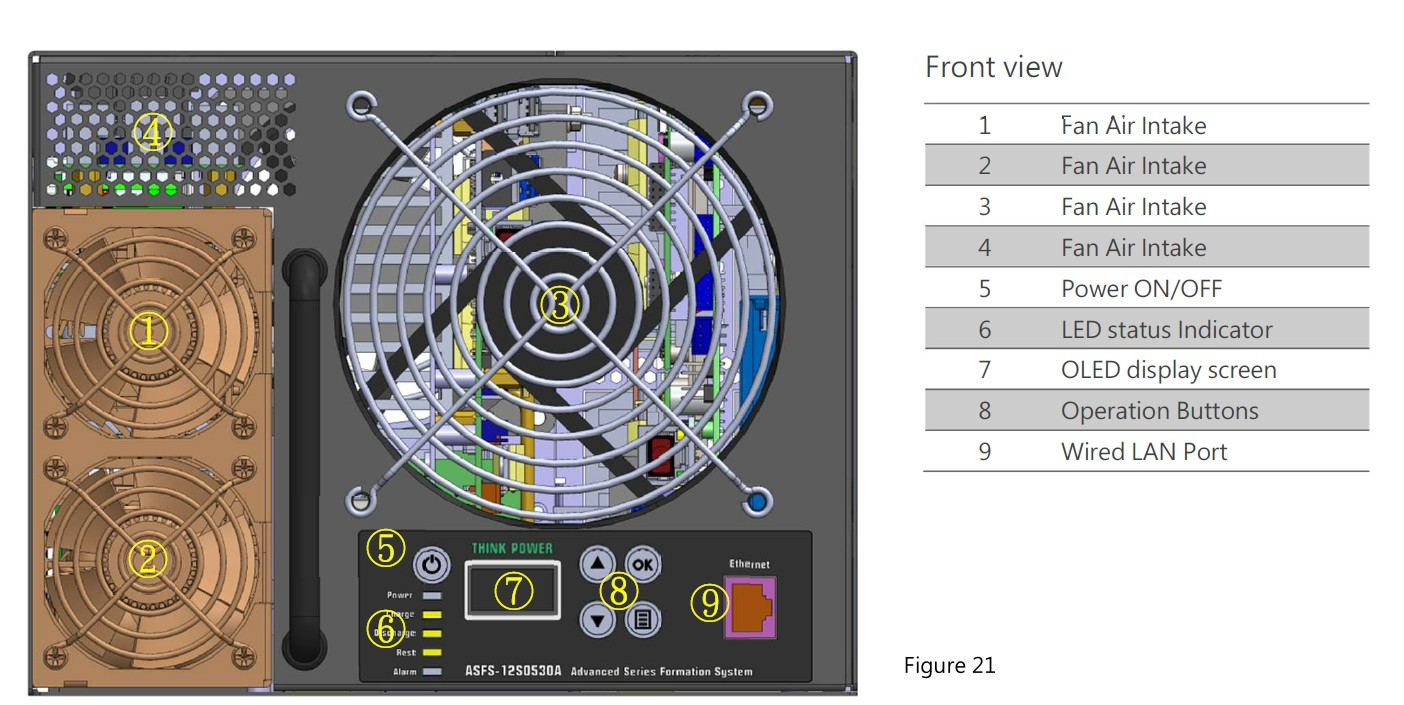

Stand-alone Control System

Static Control:

The ACFS-SCD control computer and operation software are designed to operate in a static mode. The control computer and software do not participate in dynamic process stage transitions, anomaly detection, or data logging. Therefore, even if the external control computer experiences system overload, improper operation, or crashes, the operation of individual units remains unaffected.

- Executing commands such as start, pause, and stop.

- Collecting recorded data from completed process units.

- Process editing.

- Integration with customer MES, ERP, or CIM systems.

Real-Time Monitoring:The operation software, connected via Wired LAN, displays the real-time status of all ACFS-SCD units.

Status includes:Voltage, Current, Temperature, Step, Step Time, Total Time, mAh, Wh, Cell Voltage, Bypass status.

Dynamic Control:

The ACFS-SCD features a built-in independent control system that manages all process control, fault detection, data logging, operation records, fault logs, and more.Each unit autonomously retains the complete data of the last 20 tests and stores up to 2,000 fault and operation records.

Firmware Updates:

ACFS-SCD control system firmware can be updated directly through the ThinkFM software without the need to disassemble any equipment.

Independent Single-Module Swapping

Simple Module:ACFS-SCD units function like industrial power modules, allowing maintenance or replacement tasks to be completed with minimal manpower.

No Configuration Needed:ACFS-SCD units only require an IP address input via the operation software for updates, with no additional configuration required.

I/O Interface

Specification

| Model | ACFS-12S0530A | |||

| AC Input | 1Φ/3W/AC230V;47~63 Hz;12A @ Full load;L-N-E; | |||

| Load Range | -10V ~ 60V;0.01A ~ 30.000A | |||

| Output Function | Charge | CC | ||

| Discharge | CC | |||

| AC to DC | Charge | Range | 0.010A ~ 30.000A | |

| Resolution | 0.001A | |||

| Accuracy | ± 0.02% @ F.S. | |||

| Efficiency | > 90% @ 100% Load Note1 | |||

| DC to AC | Discharge | Range | 0.100A ~ 30.000A | |

| Resolution | 0.001A | |||

| Accuracy | ± 0.05% @ F.S. | |||

| Frequency Range | 47~63Hz determined by AC main | |||

| AC Current (Typ.) | 7.5A/230VAC | |||

| Power Factor | 0.99/230VAC @ Full load | |||

| Efficiency | > 88% @ Full load | |||

| Total Harmonic Distortion | < 3% @ Full load | |||

| Safety Standards | UL62368-1、IEC62368-1、CAN/CSA C22.2 No.62368-1、TUV BS EN/EN62368-1、EAC TP TC 004、IEC62477-1、TUV BS EN/EN 62477-1 approved | |||

| Measurement | Voltage | Total | Range | 0 ~ ±66V |

| Resolution | 0.1mV | |||

| Accuracy | ±0.1V | |||

| Cell | Range | 0 ~ ±5V | ||

| Resolution | 0.1mV | |||

| Accuracy | ±0.5mV | |||

| Scan Rate | 1~12 Cell within 100ms | |||

| Current | Range | 0 ~ ±30.9A | ||

| Resolution | 0.0001A | |||

| Accuracy | ± 0.02% @ F.S. | |||

| Impedance | Range | 1 ~ 999.999 mΩ | ||

| Accuracy | ± 2 mΩ | |||

| Check cycle | 1 ~ 99 Sec | |||

| mAh | Range | 0 ~ 720,000 mAh | ||

| Wh | Range | 0 ~ 21,600 Wh | ||

| Temperature | Range | 0℃ ~ 100℃ | ||

| Resolution | 0.1 ℃ | |||

| Accuracy | ±1 ℃ | |||

| Scan Rate | T1 ~ T4 < 1s Note2 | |||

| Cut-off Condition | Step Time | 10s ~ 999h59m59s, Resolution=1s | ||

| mAh | 1 mAh ~ 720,000 mAh, Resolution=1 mAh | |||

| Voltage Threshold | 0 ~ 5V, Resolution=1 mV | |||

| Cut-off Voltage | 0 ~ 5V, Resolution=1 mV | |||

| Bypass | Start Cell Bypass | Yes | ||

| Single Cell Bypass | Yes | |||

| All Cell Bypass | Yes | |||

| Bypass Switch Time | Within 10ms | |||

| Bypass Spikes | Charge | Bypass spikes are undetected | ||

| Discharge | Current ripple Ip-p is controlled under 300mA within 1ms. | |||

| Switching Lifetime | > 100,000 @ Full load | |||

| Protect | System | OCP、OVP、REVP、Fuse | ||

| Cell Bypass Unit | Cell REVP、Cell OVP、Fuse | |||

| Fixture Tray Ambient Temperature | COTP | |||

| Equipment Inlet Ambient Temperature | EOTP | |||

| Node Circuit Impedance Check Per Cell | 0.01Ω ~ 50Ω | |||

| Recording Interval | 1s ~ 999h59m59s | |||

| Offline Recording | 20,000,000 Point,Over 5555 hours | |||

| Controller | 0.9”OLED | Equipment Information Display、IP | ||

| Indicator LED | Power On/Off、Charging、Discharging、Rest、Alarm | |||

| Button | Start、Stop、Pause、Resume、Equipment Information Query | |||

| Buzz | Alarm | |||

| Wired LAN | 10M/100M/1000M TCP-IP | |||

| Operating Environment | 10 ~ 40℃;20 ~ 90 %HR | |||

Note1:Test Lead 10WAG/1M

Note2:T1~T4 (Fixture Tray Ambient Temperature)

One year warranty.

新科電力科技股份有限公司

Think Power Technology Co., Ltd.

新北市五股區五權三路25號2樓

TEL:+886-2-22902095 FAX:+886-2-22900586

Email:sales@think-power.com.twwww.think-power.com.tw

This Document specification is for reference only and is subject to change without prior notice.