- Series Charging and Discharging Cell Formation System

- Charge and Discharge-Discharge energy recovery series

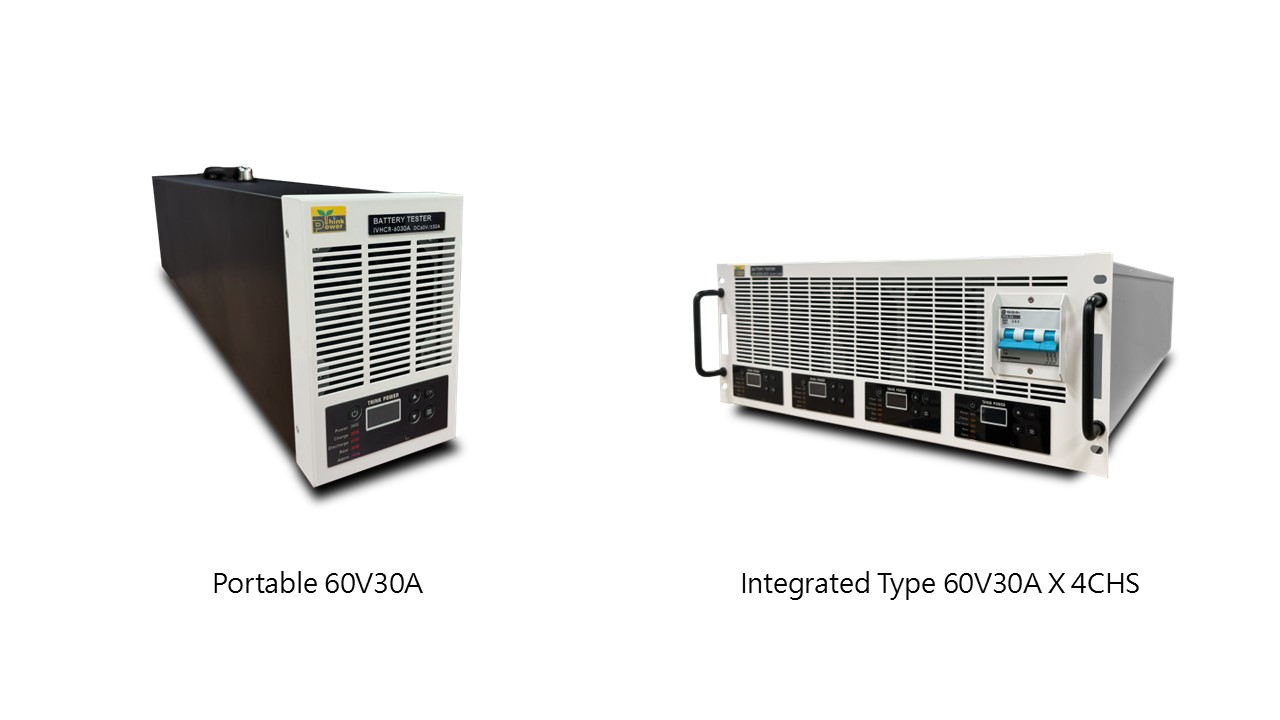

- Charge and Discharge Test Equipment-Portable

- Charge and Discharge Test Equipment-Single Independent Module

- Charge and Discharge Test Equipment-Low Current

- Charge and Discharge Test Equipment - Single machine multi-Channel series

- Charge and Discharge Test Equipment-High-speed Recording R Series

- Battery Management System BMS - PCBA Tester

- Battery Semi-test / Final test Testing Equipment

- Calibrator Equipment

- Peripheral Devices R series

- Peripheral Devices Thinklab series

- Software and hardware manual for the portable device

ESG Low-carbon emission reduction

High Efficiency Low Energy Consumption High Precision

Volume Reduction < 50%

Discharge Energy Recovery > 88%

Precision Control < 0.02%

100% Full Wattage

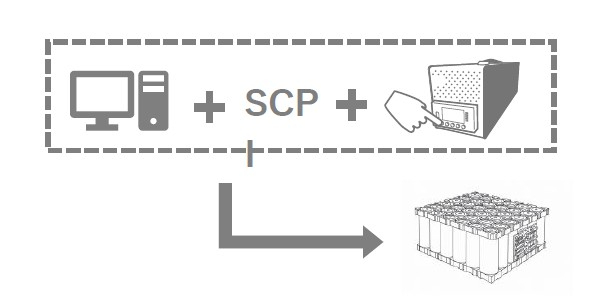

Stand-alone Control

Supports parallel operation

Complete Communication Peripherals

CAN 2.0SM

Bus

I2C

UART

RS485

I/O Controller

Cell Voltage Scanner

Cell Temperature Scanner

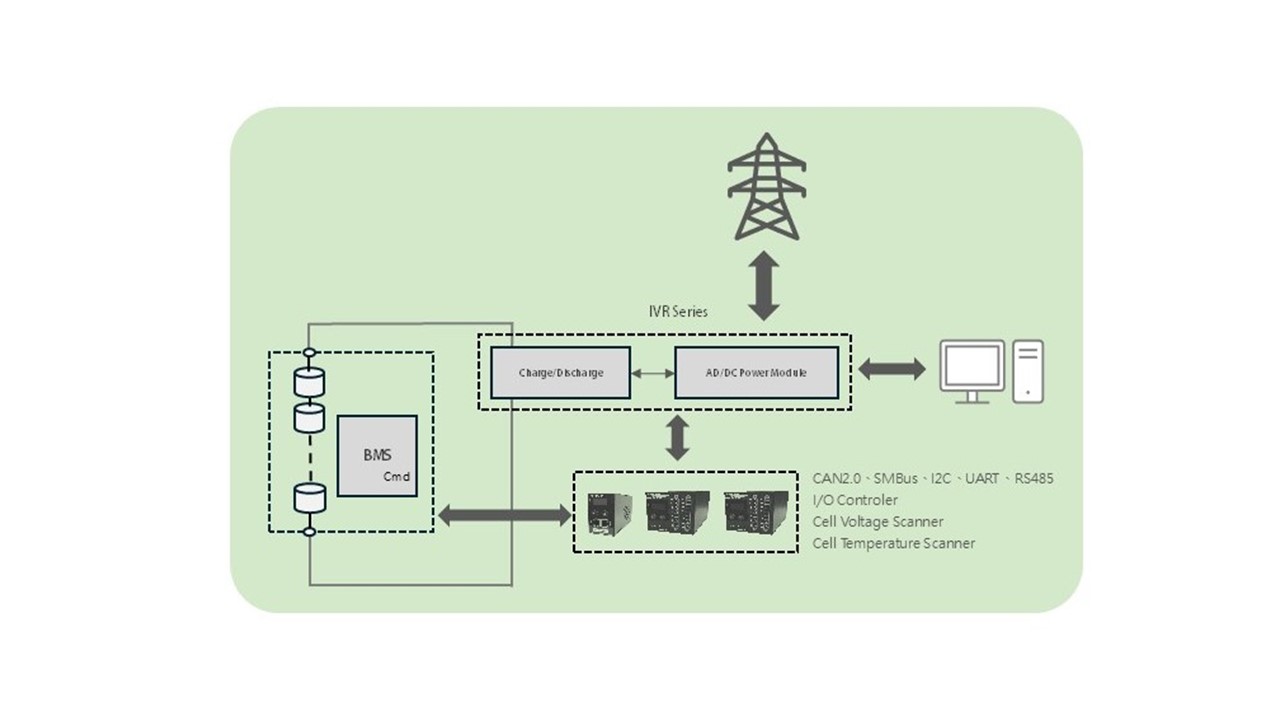

IVR Series –

Next-generation Battery Charge/Discharge Testing Platform

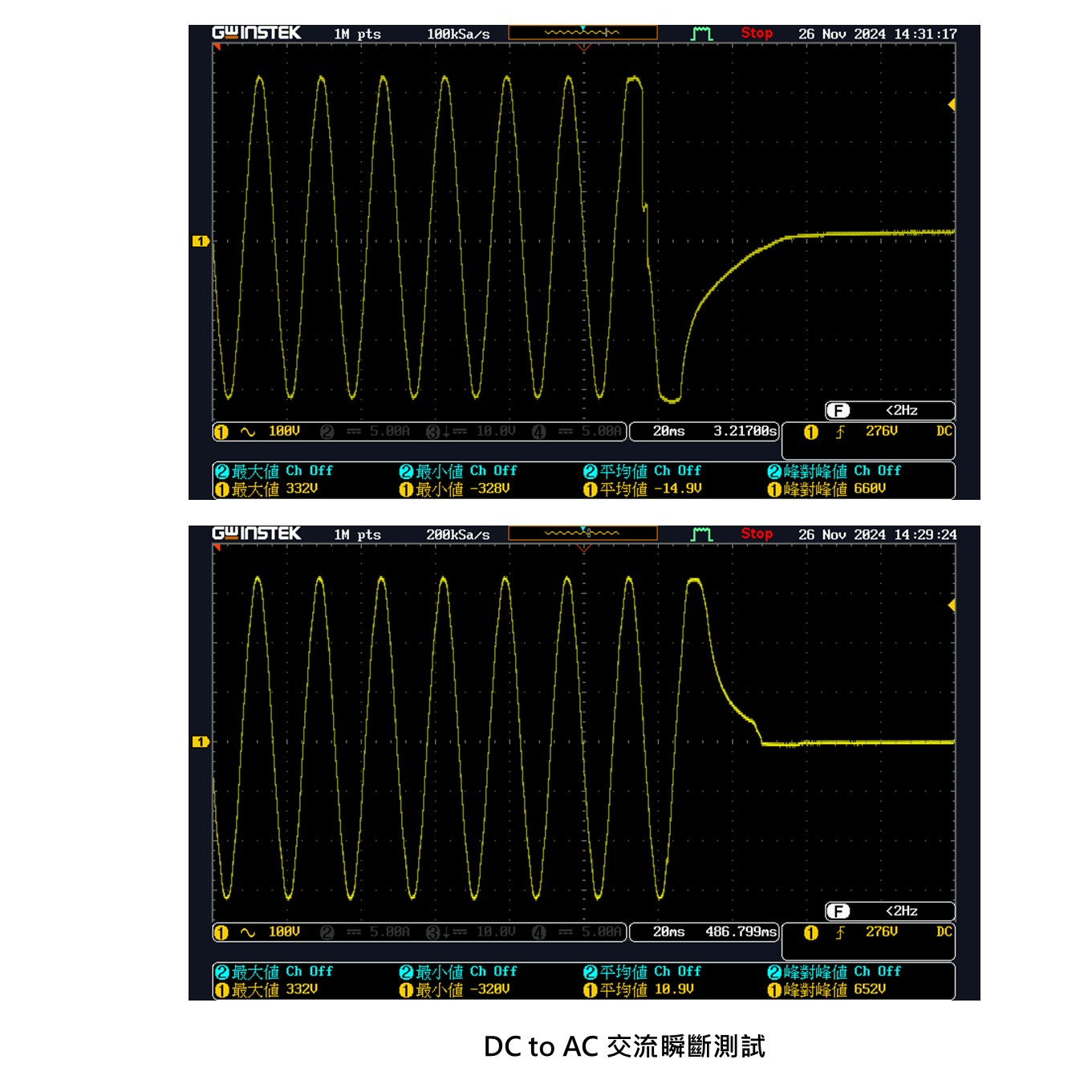

Featuring a bidirectional regenerative power design, the system converts discharge energy into AC power with over 88% efficiency, minimizing heat loss and cutting carbon emissions.

With a built-in stand-alone control engine, the system ensures voltage and current accuracy within ±0.02%, far beyond traditional DC/DC devices.

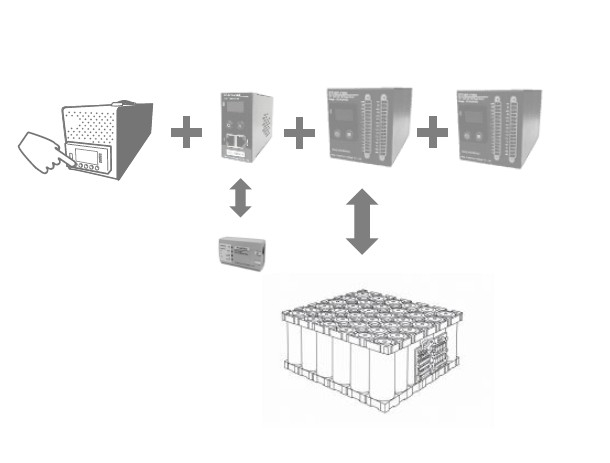

The IVR testing system features CAN 2.0, SMBus, I²C, UART, and RS485 interfaces, with expandable I/O, voltage, and temperature scanners—meeting versatile testing needs from single cells to BMS-equipped packs.

The IVR system features modular scalability, compact 19U design, and efficient energy recovery—cutting lab power and cooling costs while helping enterprises meet ESG goals. With high efficiency, low energy use, high precision, and full communication support, it delivers the most reliable and economical solution for both R&D and production testing.

Application:

Battery Pack Performance and Specification Testing

Battery Pack Communication Test

Power Battery Pack – On-site MaintenanceEnergy Storage System – On-site Maintenance

Industrial Battery Pack Production

General Cell ApplicationsBattery module final/semi test

SCPI Command Support for Secondary Development

System Advantages:

Discharge Energy Recovery Efficiency> 88%Output Control Accuracy< 0.02%、

Measurement Accuracy< 0.02%

100% Full Wattage

Complete Communication Peripherals

Modular Solution – Cell Characteristic Measurement Support

Allow Stand-alone Control (Offline)

AC/DC Bidirectional Power Module,Safety CertificationIEC62477-1、IEC62116、TUV/UL 62368-1、CB/UL/TUV 62368、CE

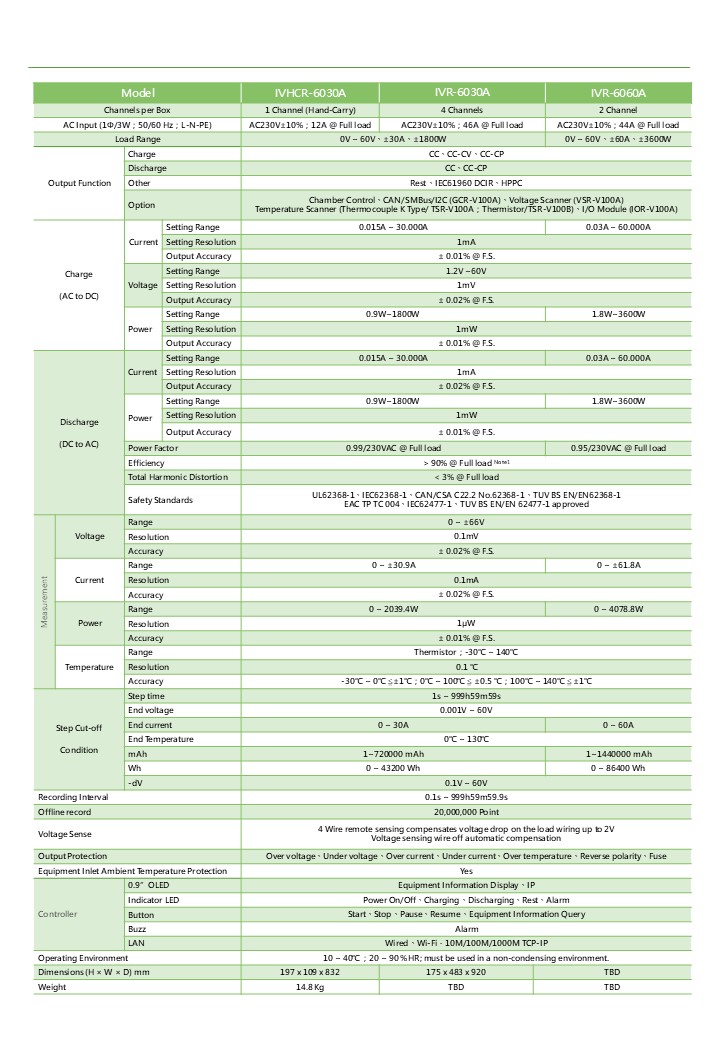

Specification

A p p l i c a t i o n M o d e

A p p l i c a t i o n D e s c r i p t i o n

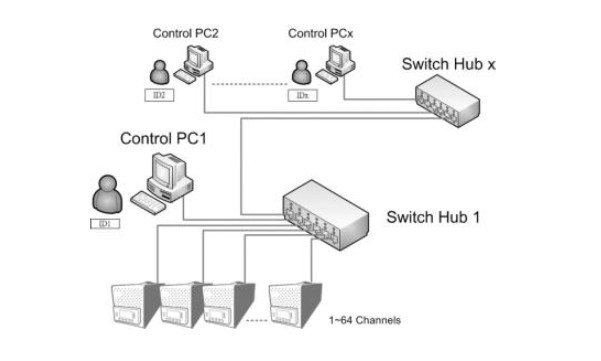

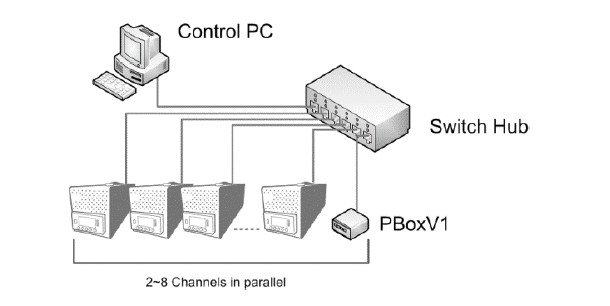

Using Standard LAN Connection

Allows multiple users to connect simultaneously from different PCs.The device is factory-set to a static IP, but users may reset it to a dynamic IP ifneeded.

Test data from the device can be automatically routed to designatedpersonnel based on user settings.

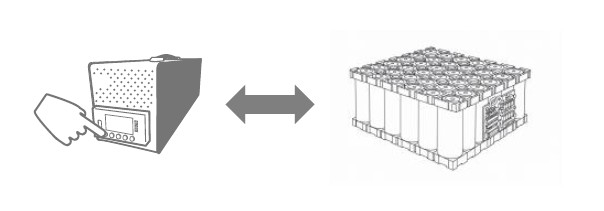

Battery Pack Characterization Tests

Battery pack capacity test, overload protection test,charge/discharge test,

Reliability test, aging test, finished/semi-finished product test

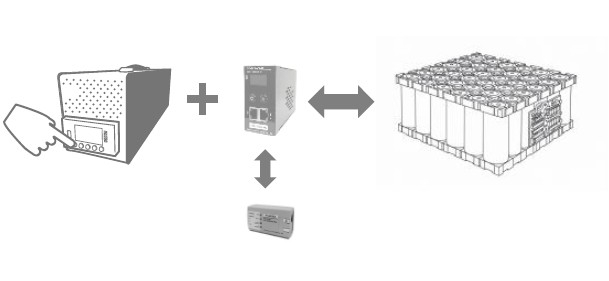

Battery Pack + Communication Testing

Battery pack capacity test, overload protection test, charge/dischargetestReliability test, aging test, finished/semi-finished product test,communication testCAN 2.0, SMBus, I²C, UART, RS485Obtain stageswitchingor termination conditions of battery pack tests throughcommunication

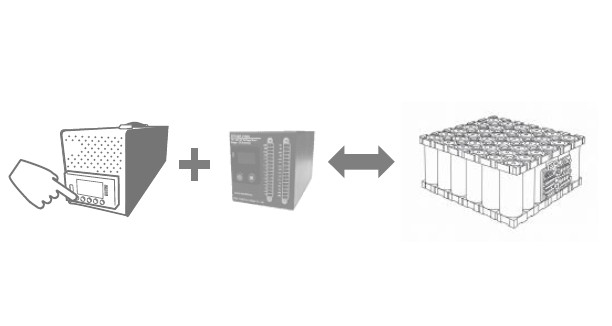

Battery Pack + Cell Characteristic Testing (Voltage, Temperature)

Battery pack capacity test, overload protection test, charge/discharge test,reliability test.

Aging test, finished/semi-finished product test, cell balancing test, celltemperature test.

Cell Voltage Scanner obtains individual cell voltages as conditions for teststage switching or termination.

Cell Temperature Scanner obtains individual cell temperatures, or packspecifiedlocation temperatures, as conditions for test stage switching ortermination.

Battery Pack + Communication + Cell Characteristic Testing(Voltage, Temperature)

Battery pack capacity test, overload protection test, charge/dischargetestReliability test, aging test, finished/semi-finished product test,communication test, cell balancing test, cell temperature testCAN 2.0, SMBus,I²C, UART, RS485Obtain stage-switching or termination conditions of batterypack tests through communicationCell Voltage Scanner obtains individualcell voltages as conditions for test stage switching or terminationCellTemperature Scanner obtains individual cell temperatures, or pack-specifiedlocation temperatures, as conditions for test stage switching or termination

PBOX v1 Allows 8 Channels in Parallel OperationSoftware-configurable for 2 to 8 channels to be paralleled or de-paralleled,without requiring hardware modifications.

SCPI Support for Third-Party Development

SCPI Commands for Third-Party Development – CompleteDocumentation & Validation Tools Provided

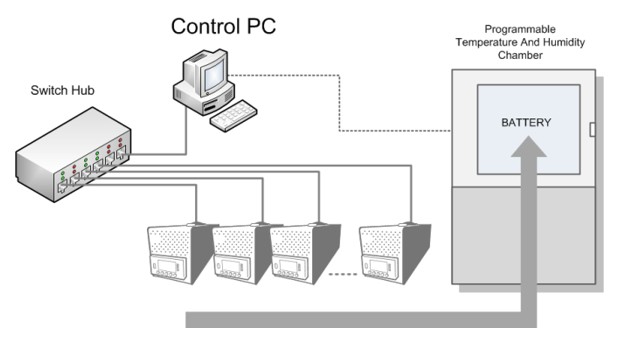

Integration with Programmable Temperature & HumidityChambers

The ThinkRP testing process allows charge/discharge channels to bepaired with programmable temperature and humiditychambers.Users can configure multiple charge/discharge channelsto operate within the same chamber for large-scale batteryenvironmental testing

Built-in Standard HPPC Test

Hybrid Pulse Power Characterization Test (HPPC)Industry’s onlysolution offering fully customizable HPPC testing, or testing basedon built-in standards.Automatically generates test curves.

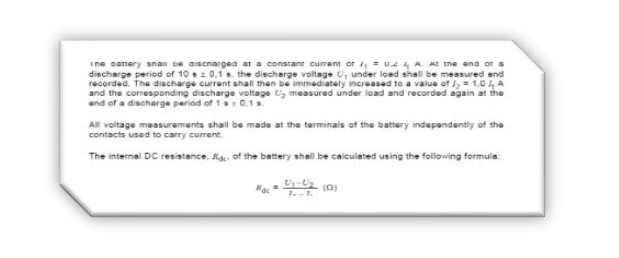

Built-in IEC 61960-3 DCIR Standard Test

Measurement of the internal DC resistance (DCR)Can be embeddedinto testing processes, enabling DCR measurement after variouscharacteristic tests.Provides parameter customization or testingbased on built-in IEC standard, with automatic data generation.

Built-in SBS Special Test

With GCR-V100A + GR300A, SBS special tests can be performed.

◼ Smart Charge

◼ SPPCurrent

◼ SusPeakPower

Test Process I/O Handshaking

With GCR-V100A + IOR100A

According to test script requirements, the process can trigger Relaysor DO signals to activate the DUT (Device Under Test).

DI can be used to detect DUT I/O Hi/Lo states, which then controlthe flow of the test script.

World-Class Safety Standards and Certifications

Safety Standards / Certifications:

Unlike non-standard customized products, the AC/DC bidirectional power module complies with IEC 62116, TUV/UL 62368-1, CB/UL/TUV 62368, and CE certification requirements. The AC parallel function is designed in accordance with IEC 62477-1 standards. This not only ensures product stability under high-load operation but also significantly reduces potential risks during system operation.

MIT-Compliant Global Standard Products with Reliable Quality:

Utilizing globally recognized mass-production components ensures consistency and supply chain stability.

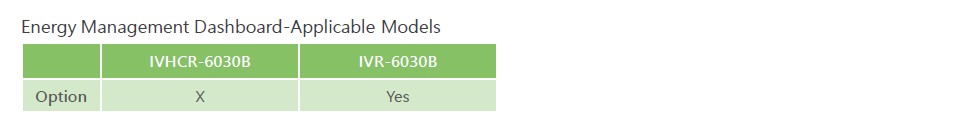

Energy Management Dashboard/Option

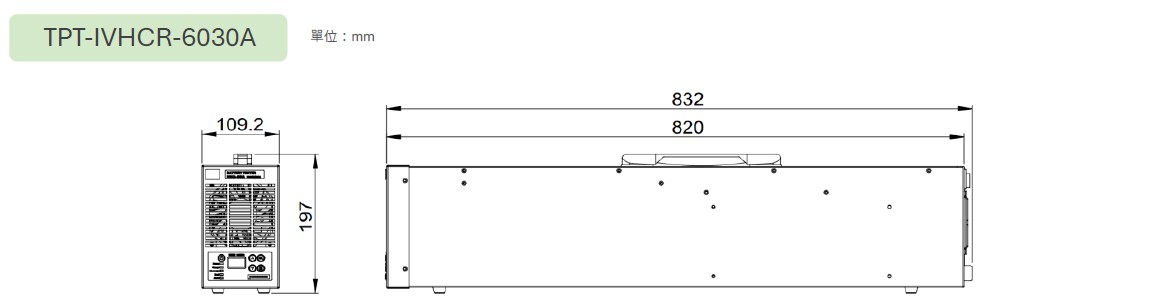

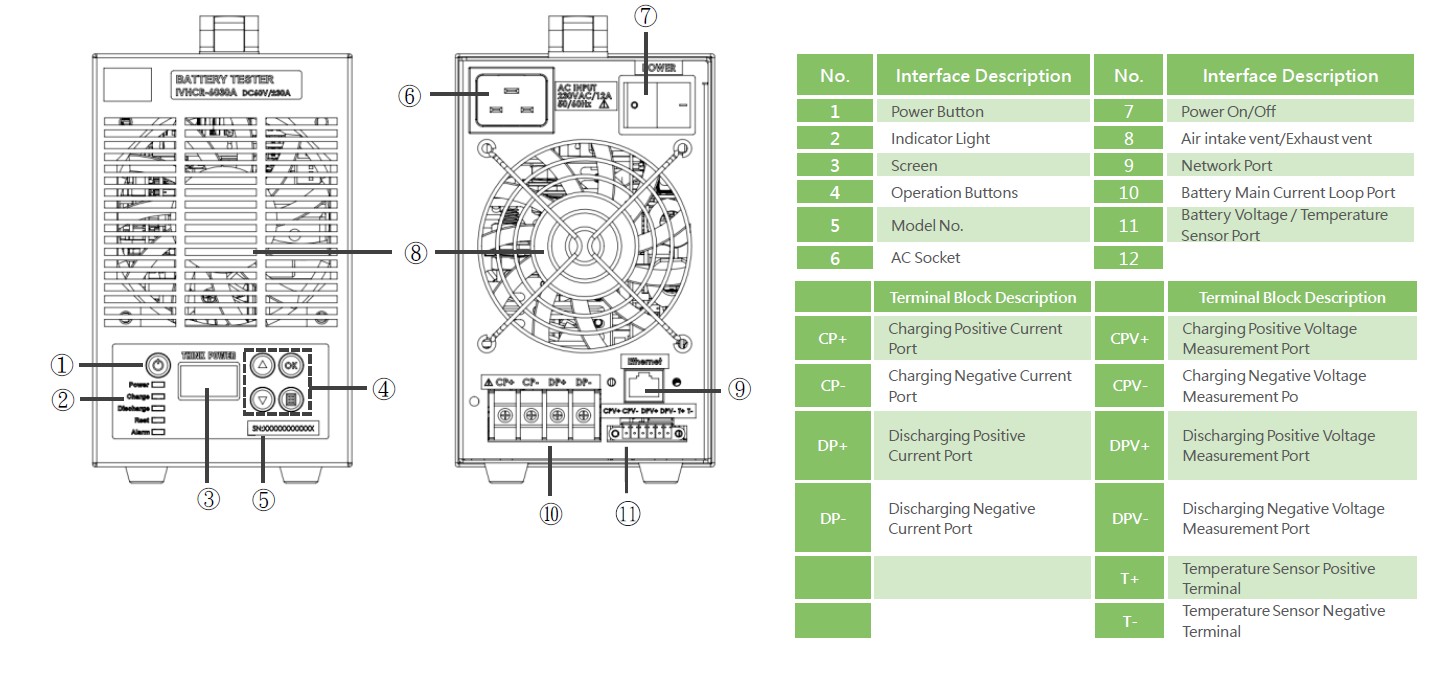

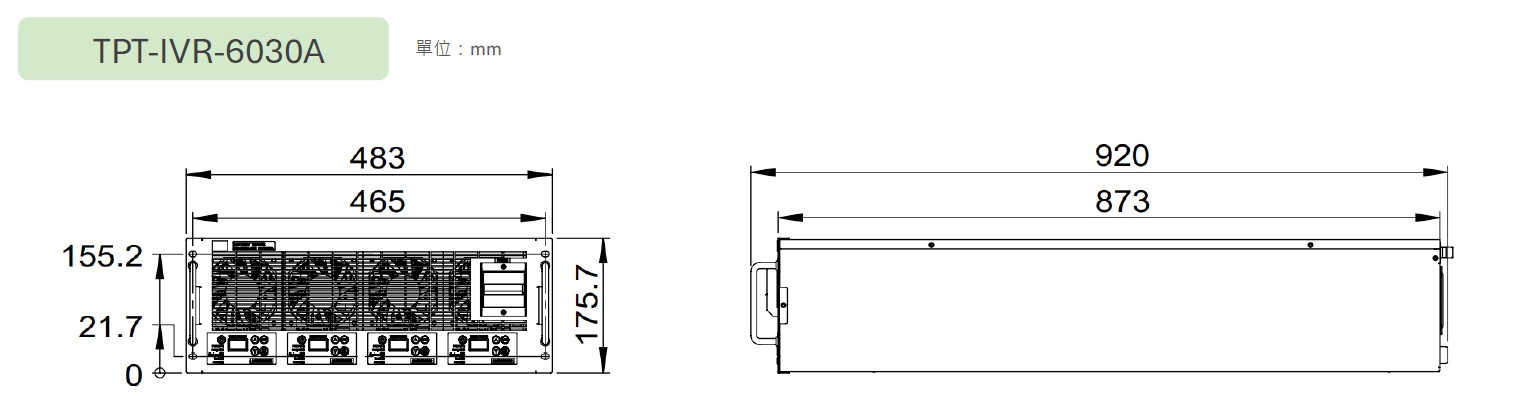

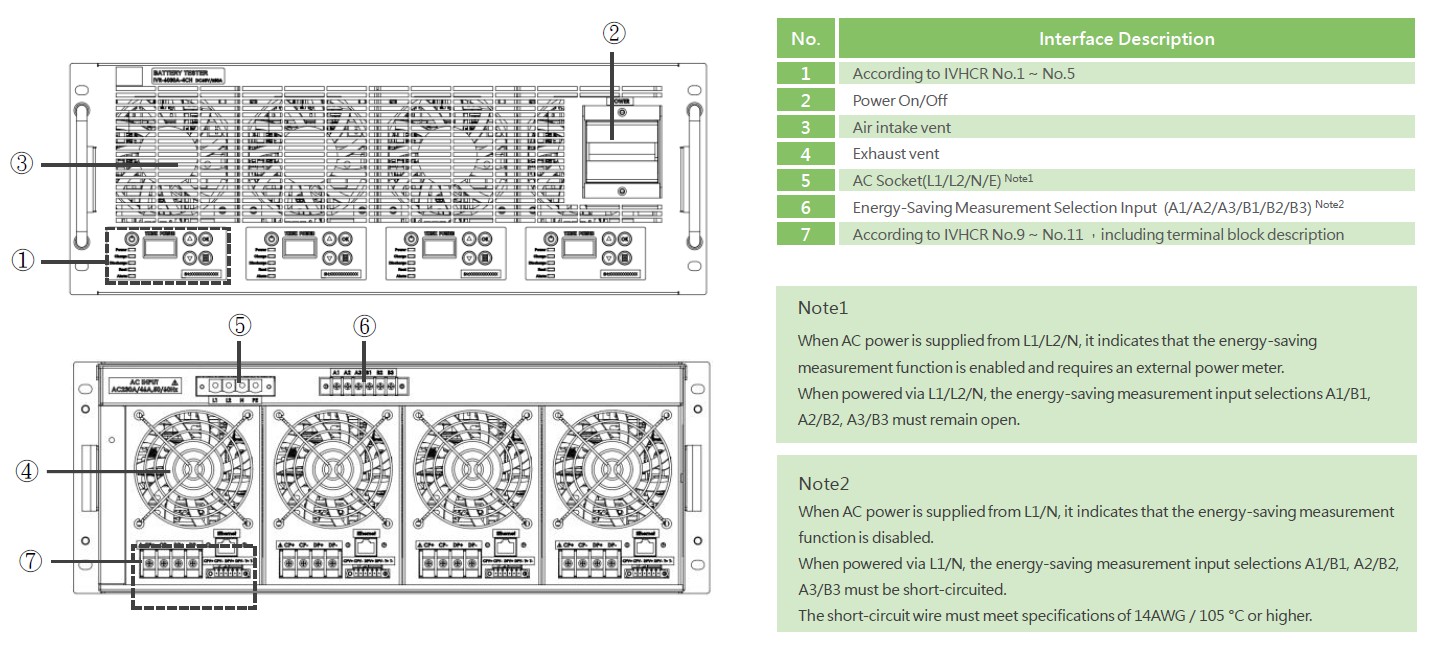

Mechanical Specification